#Fusion 360 assembly how to#

Interested in learning more about Autodesk Inventor? Learn how to project geometry in an assembly and update multiple iProperties at once in our previous blog posts. Watch the video tutorial below to see in action how to remove the material of a part in an assembly using the outside surface of a mating part in Autodesk Inventor.

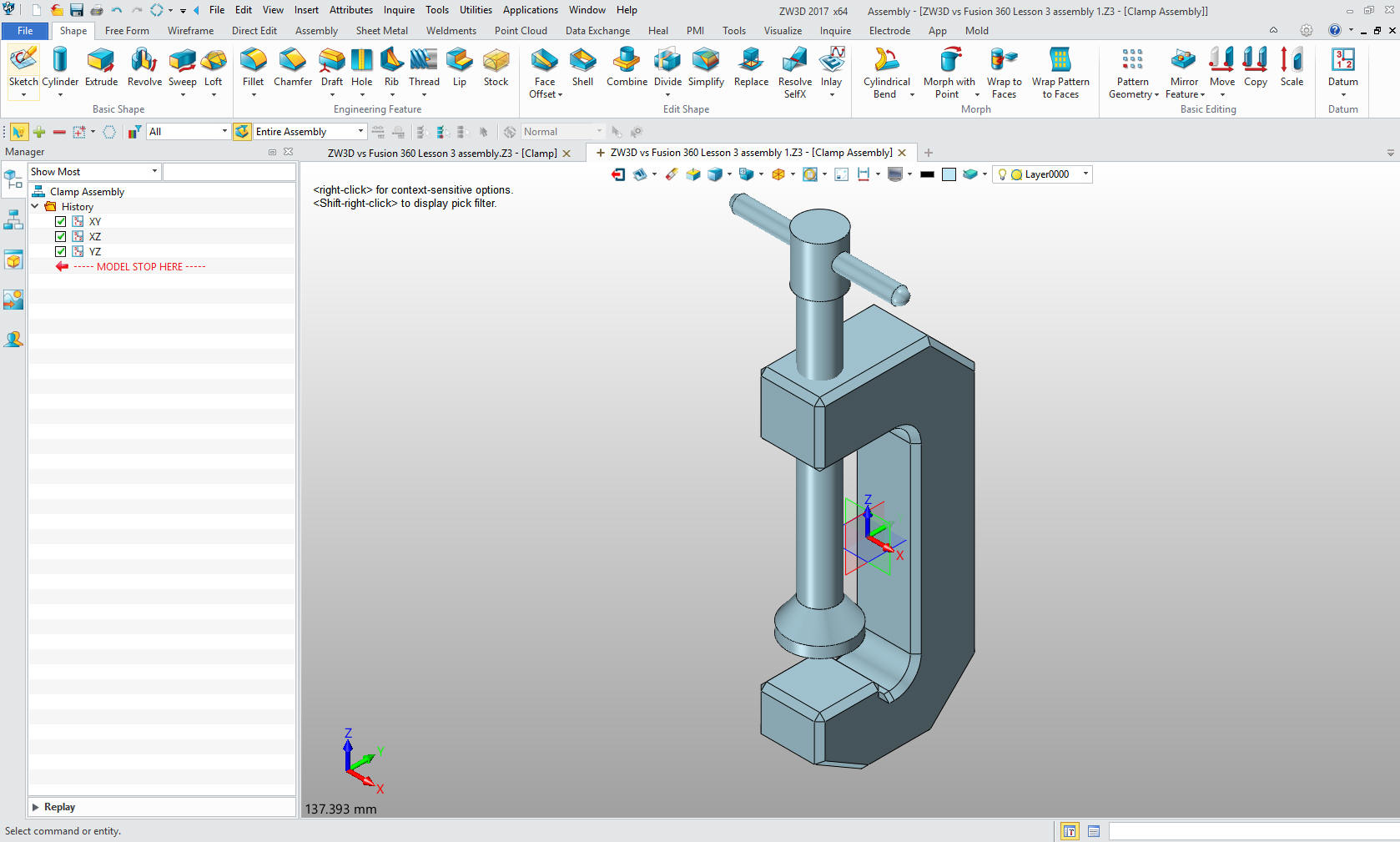

Step 6: If a lump or void remains, you can remove it with the Delete Face command. Step 5: With the Sculpt command, select the surface you would like to remove. Step 4: Navigate to the Surface panel and select the Sculpt command. Then, click on the solid that will be used for creating the cut. Step 3: From the Copy Object pop-up, select Body. Step 2: From the Modify panel, navigate to Copy Object. Step 1: Edit the part you’re looking to remove the material from. We’ll be demonstrating the following steps: When prompted to pick a plane to put the sketch on, select the bottom edge face of the brick. Click Create Sketch in the Fusion 360 Solid Modeling menu. This can provide immediate time-savings to your designs and prevent you from having to create 2-3 sketches to achieve the same result. You will need to apply this step to each of your individual brick files before we begin the assembly. But, Fusion supports a 'Rigid' Joint, which established a rigid connection between components, which in your case seems like what you want. In this Autodesk Inventor tutorial, we’ll be looking at how to subtract one solid from another in an Inventor assembly by using a mating part. 27, 2019 by Manufacturing Applications Consultant, Dave Breiner You’re provided a downloadable Fusion 360 model used for each step in the exercise and the exercise ends with a walkthrough video for you to become fully confident in your new assembly creation skills.Posted on Feb. The solution helps Fusion 360 users create and select a tool assembly, choose the stock material, and get the tool and cutting data recommendations. The last section in the course focuses on “Distributed Design Strategies,” which addresses scenarios where teams of designers are collaborating on a single design and work on smaller sections of that design.Įach of these sections wraps up with hands-on exercises, which allow you to master the concepts and techniques learned throughout the course. Sandvik Coromant, a Swedish supplier of cutting tools and services to the global metal cutting industry, presented CoroPlus, a plug-in extension for Fusion 360 for CAM programming. Understanding Joint creation is a crucial aspect of creating assemblies, since it’s a relatively new workflow in CAD modeling and is significantly different than the commonly used method of adding mates to parts.

The next section focuses heavily on creating Joints and how they control the positions and motion of the components in the assembly. The Fusion 360 Assemblies course begins by walking through some higher level concepts of assembly structure, including topics like the differences between bodies and components as well as how to insert other designs into a main assembly. Components can then have joints applied, which relates the parts to one another and enables certain degrees of motion. With Fusion 360 you can create all of the parts in a single design, and then set them as “components” in an assembly. With many other CAD programs the parts must be designed first, and then inserted into a separate assembly file. /rebates/2fcourse2fassemble-parts-and-components-in-fusion-360-d2f&. The advantage comes from being able to design both parts and assemblies in the same design space.

Fusion 360 offers one of the most powerful and convenient workspaces for bringing your assemblies to life.

0 kommentar(er)

0 kommentar(er)